Fine Natural safely produces the products while protecting them from harmful factors such as contamination and deterioration

The inside of the GMP is divided into clean and general areas. Processes for concentration liquid, extract filling, and packaging of other products are carried out inside of the GMP equipped with air conditioning facilities to block and safely produce products as much as possible to prevent contamination and deterioration.

Production capability

-

Mixing/combining

-

Making globulus

-

Drying

-

Coating

-

Small globulus

with the existing

method of manufacturing- · Rough surface, coarse density,

irregular form of small globulus - · Uncomfortable scent from herbs,

grains, vegetables, etc. - · The discomfort when you swallow it

- · A single color, brown tone

- · Rough surface, coarse density,

-

The differentiation of

Fine Natural’s

globulus.- ·High density, consistent shape, smooth and glossy.

- ·Small globulus with the scent

(You can choose according to your preference) - ·Comfortable when swallowing

- ·Available for various colors

-

Patent

application- ·Small globulus with increased convenience of intake.

- ·How to make / coat / implement small globulus

- ·A coating method that enhances color development implemented on the surface

Target (designed) production capacity |

1 day:

500kg, monthly production capacity: 10t

| Category | Item | Size | Number of equipment (Type) |

1 day production capacity |

Monthly production capacity |

|---|---|---|---|---|---|

| Liquid type |

Stick pouch (liquid) |

3 ~15ml |

3 columns - 1 | 80,000 bags | 1,600,000 bags |

| 1 columns - 2 | 30,000 bags | 600,000 bags | |||

| liquid pouch (3 columns) |

60 ~110ml |

2 | 60,000 bags |

70ml ~100ml 2 millions bags |

|

|

liquid pouch (single column) |

60 ~110ml |

4 | 32,000 bags | ||

| 20ml | 2 | 20,000 bags | 400,000 bags | ||

| 30ml | 1 | 10,000 bags | 200,000 bags | ||

| Standing pouch (rotating type) |

20 ~150ml |

1 | 14,000 bags | 300,000 bags | |

| Standing pouch (single column) |

100 ~180ml |

1 | 10,000 bags | 200,000 bags | |

| Concentration liquid type |

kg | - | - | 7~8t production | |

| 100kg | Automatic filling of bottles |

10,000 bottle | 200,000 bottles filling |

||

| 240kg | Automatic filling of bottles |

10,000 bottle | 200,000 bottles filling |

Strengths of liquid sticks

- · Precise content and usage

- · 4 units to produce stick pouches / monthly production capacity 2,200,000 pouches

- · Production of liquid sticks in various sizes of 3-15ml

-

01

Bonsam

washing, steaming, drying, sun drying

(Main ginseng) -

02

Concentrated liquid

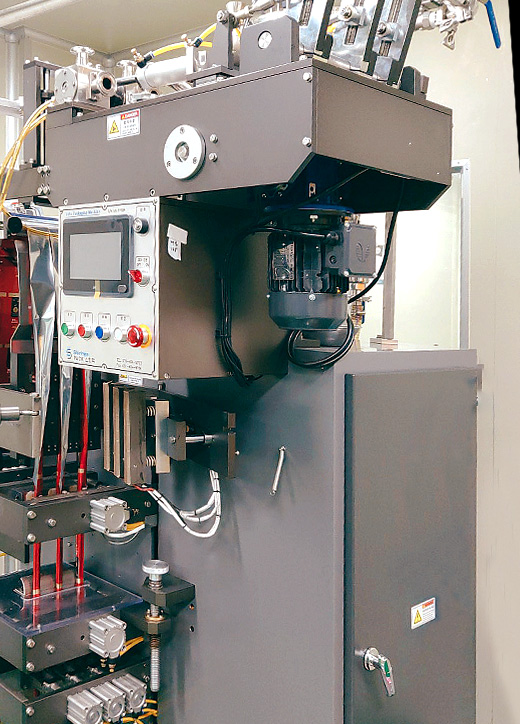

extractor, concentrator, NC concentrator, fermentation tank, stirring tank, aging tank, automatic bottle filling line -

03

Sugared

Washing, drying, metal detector, sugaring machine, vacuum packaging machine, sealing machine

(Candied/Honeyed slices) -

04

Pouches

Extractor, mixer, and various standard filling sticks -

05

Tablet

Mixer, tablet machine, PTP packaging filler -

06

Globulus products

large type, small type -

07

Granule

mixer, granule molding machine, dryer granule sorting machine, slope packaging machine